Bitumen Softening Point: A Critical Parameter and the Influence of Polymer Modification

Bitumen, also known as asphalt, serves as the essential binding agent in asphalt pavements. Its properties directly influence the performance and durability of these critical transportation infrastructure elements. One crucial property of bitumen is its softening point, which plays a significant role in pavement resistance to deformation and cracking.

Understanding Softening Point

The softening point of bitumen refers to the temperature at which it transitions from a solid or semi-solid state to a more fluid state. This transition is crucial for several reasons:

- Workability: During pavement construction, bitumen needs to be heated to a workable consistency for proper mixing with aggregates and compaction. The softening point provides a benchmark for determining the appropriate heating temperature to achieve optimal workability without compromising the bitumen’s binding properties.

- Performance at High Temperatures: In hot weather conditions, pavements experience elevated temperatures. Bitumen with a high softening point exhibits greater resistance to softening and deformation, minimizing rutting and potential pavement failure.

- Low-Temperature Performance: While high-temperature performance is crucial, low-temperature behavior also holds significance. Bitumen with a very high softening point might become excessively brittle at low temperatures, increasing the risk of thermal cracking.

Measurement of Softening Point

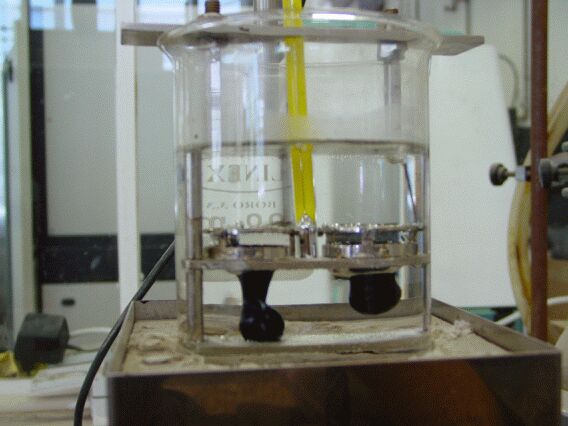

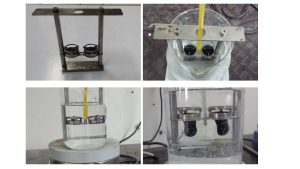

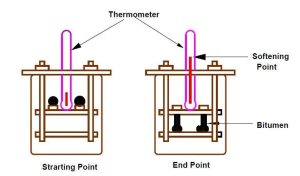

Standardized test methods are employed to determine the softening point of bitumen. A commonly used method involves the Ring and Ball Apparatus (R&B). This apparatus utilizes a metal ring filled with bitumen and suspends it in a bath of heated liquid. A steel ball is placed on top of the bitumen in the ring. As the bath temperature increases at a controlled rate, the bitumen softens. The temperature at which the softened bitumen allows the steel ball to fall through the ring is recorded as the softening point.

Factors Influencing Softening Point

Several factors influence the softening point of bitumen:

- Crude Source: The origin of the crude oil from which the bitumen is derived plays a role. Different crude sources yield bitumen with varying chemical compositions, which can impact softening point.

- Refining Process: The refining process employed to extract bitumen from crude oil can influence its softening point. Techniques that remove lighter fractions typically result in bitumen with a higher softening point.

- Asphaltene Content: Asphaltenes are a class of heavy, high-molecular-weight hydrocarbons present in bitumen. Higher asphaltene content is generally associated with a higher softening point.

The softening point of bitumen directly influences its performance in pavements by impacting its:

-

Viscosity: Bitumen with a lower softening point exhibits lower viscosity at higher temperatures. While this eases workability during construction, it can lead to excessive fluidity under hot weather conditions, increasing the risk of rutting. Conversely, bitumen with a very high softening point might be too stiff at lower temperatures, hindering proper compaction and potentially leading to thermal cracking.

-

Temperature Susceptibility: The rate at which bitumen’s viscosity changes with temperature is another crucial consideration. Bitumen with high temperature susceptibility exhibits a dramatic decrease in viscosity with increasing temperature. This can exacerbate rutting issues in hot climates. PMBs often demonstrate improved temperature susceptibility, offering a more gradual viscosity change across a wider temperature range.

Data on Softening Point Variations:

-

Unmodified Bitumen: The softening point of unmodified bitumen typically falls within the range of 35°C to 60°C (95°F to 140°F), depending on the crude source and refining process.

-

Polymer Modified Bitumen (PMB): The incorporation of polymers generally increases the softening point of bitumen. The specific increase varies depending on the polymer type, dosage, and compatibility with the bitumen. Here’s a breakdown of some common PMB types and their typical softening point ranges:

- SBS Modified Bitumen: +5°C to +15°C (9°F to 27°F) increase compared to unmodified bitumen.

- SEBS Modified Bitumen: +3°C to +10°C (5°F to 18°F) increase compared to unmodified bitumen.

- Elastomeric Polymer Modified Bitumen: Can offer even higher increases in softening point, ranging from +10°C to +20°C (18°F to 36°F) compared to unmodified bitumen.

-

Additional Factors Affecting Softening Point:

- Ageing: Bitumen undergoes a natural ageing process over time. This process can lead to an increase in softening point as the lighter fractions volatilize, leaving behind a more viscous material.

- Additives: Specific additives, such as anti-stripping agents, can slightly influence the softening point of bitumen.

Optimizing PMB Selection for Softening Point:

Selecting the optimal PMB for a specific application requires careful consideration of several factors:

- Performance Grade (PG): The American Association of State Highway and Transportation Officials (AASHTO) has established a Performance Grading (PG) system for asphalt binders. This system considers both the high and low-temperature performance of the binder, with a designated PG grade specifying the minimum and maximum pavement service temperatures. Selecting a PMB with a PG grade that aligns with the anticipated climatic conditions ensures optimal performance at both high and low temperatures.

- Traffic Volume and Loading: Heavier traffic volumes and loads necessitate PMBs with a higher softening point to withstand increased stresses and strains. However, extreme increases in softening point should be balanced against potential low-temperature brittleness concerns.

- Environmental Regulations: Some regions might have regulations governing the use of specific polymers or additives in PMBs. These regulations may influence the selection process.

Polymer Modification and its Impact

The addition of polymers to bitumen, leading to the creation of polymer modified bitumen (PMB), significantly influences its softening point. The specific type and dosage of the polymer play a critical role in the degree of change observed. Common polymers used in PMB production include styrene-butadiene-styrene (SBS), styrene-ethylene-butylene-styrene (SEBS), and various plastomeric polymers.

In general, the incorporation of polymers into bitumen increases the softening point:

- Polymer Network Formation: Polymers act as reinforcing agents within the bitumen matrix. They create a more robust network structure, requiring higher temperatures for the bitumen to soften and flow.

- Compatibility with Bitumen: The compatibility of the chosen polymer with the bitumen is crucial. Highly compatible polymers interact and restrict the movement of bitumen molecules, contributing to a higher softening point.

Benefits of Increased Softening Point with PMBs

The increased softening point associated with PMBs offers several advantages for pavements:

- Enhanced Rutting Resistance: In hot climates, pavements experience significant thermal stress. PMBs with high softening points exhibit greater resistance to softening and deformation under these conditions, leading to reduced rutting and improved pavement performance.

- Improved Workability at High Temperatures: During construction involving hot weather conditions, PMBs with high softening points maintain a workable consistency at elevated temperatures, facilitating efficient mixing and compaction processes.

Considerations for PMB Selection

While a higher softening point is generally desirable for PMBs, it’s crucial to consider other factors during selection:

- Climate and Temperature Variations: The expected temperature range in the service environment is critical. While a high softening point is beneficial in hot climates, it can lead to brittleness at very low temperatures. Selecting PMBs formulated with polymers that exhibit good thermal stability across the anticipated temperature range is essential.

- Traffic Volume and Loading: Heavier traffic volumes and loads necessitate PMBs with a combination of high softening point and good elastic recovery properties.

Softening point is a critical parameter for bitumen used in pavement construction. By understanding the factors influencing softening point and the impact of polymer modification, engineers can select appropriate bitumen or PMB grades for specific applications. Polymer modification offers a compelling approach to enhance the softening point, leading to improved rutting resistance and high-temperature performance.

Introducing Akabit, Polymer Modified Bitumen (PMB) by Tadbir Tejarat company. Akabit tackles pavement challenges by elevating the bitumen’s softening point. This translates to enhanced rutting resistance in hot climates and improved workability during high-temperature construction. click the links for further information. AkaBit EL64, EL70, and EL76.