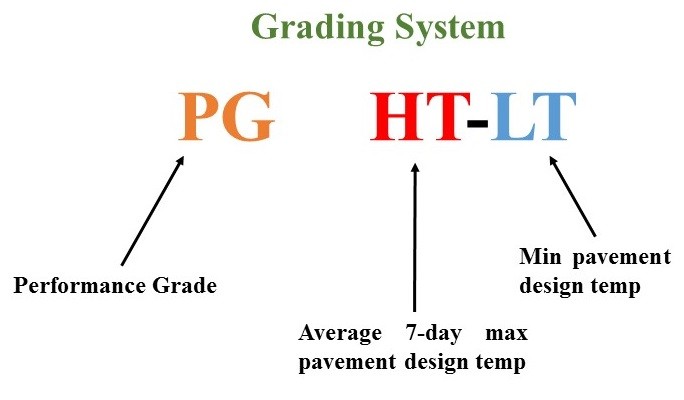

Bitumen performance grades

Performance Graded (PG) bitumen is a classification system used to characterize the rheological properties of bituminous binders. Unlike penetration grading, which focuses on consistency at a specific temperature, performance grading takes into account the bitumen’s behavior over a range of temperatures and under various loading conditions. The PG system provides a more comprehensive understanding of bitumen performance in the field. Here’s a detailed explanation:

- Temperature Range:

- Performance grading is based on the bitumen’s performance at high and low temperatures. The temperatures are specified in terms of the high and low temperatures at which the bitumen is expected to perform adequately.

- Components of PG Specification:

- The PG specification is typically expressed as PG YY-SS, where YY represents the high-temperature performance grade, and SS represents the low-temperature performance grade.

- High-Temperature Performance (PG YY):

- The high-temperature performance grade (PG YY) is determined by the Dynamic Shear Rheometer (DSR) test, which measures the resistance of bitumen to deformation under varying temperatures and loading conditions.

- For example, PG 64-22 means that the bitumen is expected to perform adequately at high temperatures up to 64°C.

- Low-Temperature Performance (PG SS):

- The low-temperature performance grade (PG SS) is determined by the Bending Beam Rheometer (BBR) test, which assesses the stiffness of bitumen at low temperatures.

- For example, PG 64-22 means that the bitumen is expected to perform adequately at low temperatures down to -22°C.

- Binder Aging:

- Performance grading also considers the aging of bitumen. The specification may include an “A” designation for bitumen that has been artificially aged to simulate the effects of long-term exposure to the environment.

- Shear Rate and Frequency:

- The DSR test evaluates bitumen at various shear rates and frequencies to simulate different traffic and environmental conditions. This provides a more realistic representation of the bitumen’s behavior in the field.

- Application in Pavement Design:

- PG grading is crucial in pavement design because it ensures that the bitumen selected for a specific region or project is suitable for the expected temperature and loading conditions.

- Variability and Tolerance:

- PG specifications include tolerances to accommodate natural variability in bitumen properties. This allows for a range of acceptable performance within the specified grade.

- Compatibility with Mixtures:

- PG grading considers the compatibility of bitumen with various asphalt mixtures, helping to ensure that the overall asphalt pavement performs well under different conditions.

Performance Graded bitumen provides a more advanced and precise approach to selecting bituminous binders for specific climates and applications, leading to more durable and resilient asphalt pavements. The PG system is commonly used in the United States and several other countries. Local specifications and standards should always be consulted for accurate information in a particular region.

Tadbir Tejarat Company is a supplier of all kinds of bitumen performance grades. This company has the ability to supply polymer or modified bitumen in different grades specially PG 64 -28, PG 70 -22, PG 76 -16 for various areas.